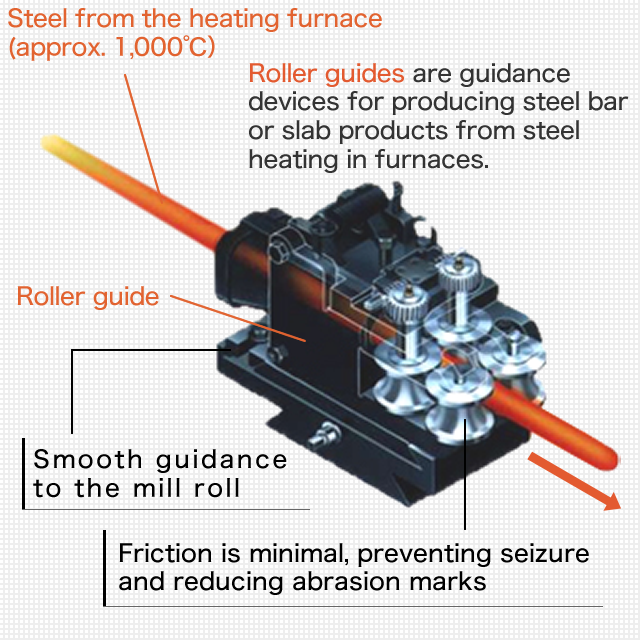

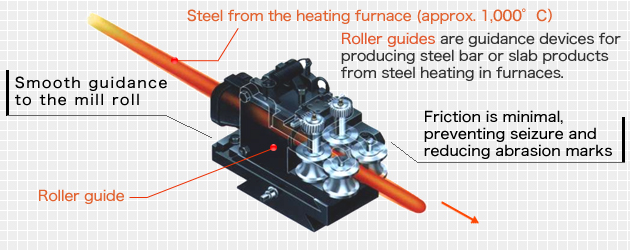

Kotobuki Sangyo Roller Guide for rolling mill are now indispensable in the world-renowned Japanese steel industry as a tool vital for the manufacture of high quality high value-added products. Since introducing a revolutionary roller guide product in 1945 we have been leading the international steel industry and introducing a number of patented products for rolling mill systems.

Guiding Equipment Steel Rolling Mill Guiding Equipment Rolling Mill Guidebox Sli Rolling Technology

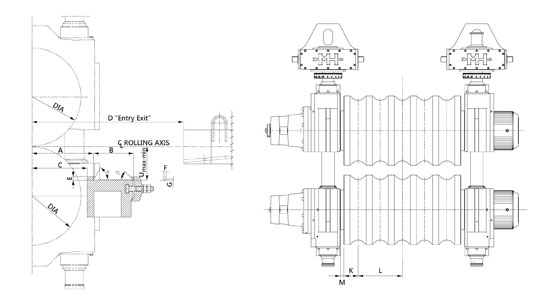

I have re done the orignial plans to all english dimensions and parts.

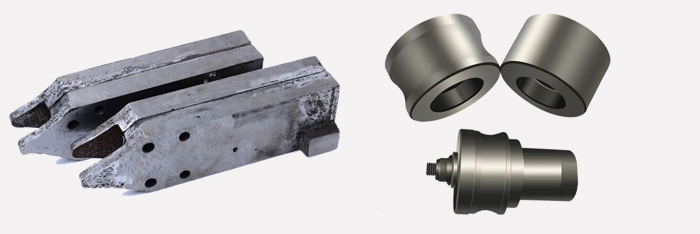

. A rolling mill guide for use in rod mills merchant mills and the like comprising a guide box two opposed blocks mounted in the guide box on opposite sides of the mill pass line and having longitudinally extending channels in their adjacent faces separate metal plates bridging the respective channels and shaped to flt closely against the sides of the stock traveling through. In principle the billet will be rolled in the same way as in conventional rolling up to the intermediate rolling mill. Roller guide box finds applications in continuous rolling operations in which the stock that is being rolled is properly twisted between each two adjacent rollers in rolling mills.

Composite tungsten carbide guide rollers are consisted of two parts steel matrix and tungsten carbide layer. Design of Mill Rolls for Rolling Mill and Material of Rolls. Features of the Rolling Mill Guides Our mill guide has excellent features such as corrosive resistance unique design and simple maintenance.

Rolling mills having single-stand type are. Ad Developed to CrushGrind Various Materials with an Optimum Result. The normal depth of tungsten carbide layer is from 5-8mmThe maximun depth could be 20-30mm.

See more ideas about rolling mill jewelry techniques jewelry making tutorials. I am going to build several extra of the parts that require mill work or lathe work if anybody else is interested. The roller guide boxes have simple design which ensures durability standards easy installation and smooth operation in diverse rolling conditions.

We have experience from decades in design and supply of rolling mill equipment. Ad Industrys Trusted Guide For Machinery Parts Supplies Services. We are catering to the requirement of Long Rolling Mills from 50000 TPY to 1 Million TPY on turnkey basis.

Cial roll pass design with designated guide Guiding is our business equipment to shape and longitudinally separate the incoming billet into two or more individual strands which will then be further rolled into finish-ed sizes. Oct 1 2018 - Explore Navanites board Rolling Mill Patterns Designs on Pinterest. Cantilever compact mill stands are.

The mill operators guide the wire rod via switches through various parts of the equalising section and cooling systems to achieve the best results irrespective of diameter and steel grade. The quality of our guide products are world famous for its. Rolling mill is used to reduce successively the thickness of the metal strip as per the requirement.

Although more convenient they sacrifice. Whether its special steel for automobiles and construction machinery or the shape and bar rolling of high-strength deformed steel for high-rise. Rail Guide Mills for Home Professional Use.

Rolling Mill Guide Design. It is provided with heavy taper roller bearings for different sections. Rolling mill rolls and roll bearings base are the core parts of the whole working stand of the rolling mill and the roll is the main part of the direct rolling mill.

Develop a cross-sectional drawing with part material and mill specificationstolerances. The composite tungsten carbide guide rollers have better save cost and same wear resistance than tungsten carbide guide rollers. When rolling final sizes with diameters of more than 115 mm the wire rod block upline of the MEERdrive PLUSis not used.

100 Free to Use. Rolling mill guide design Valentines Day is approaching it is just a month absent but There are tons of things to prepare from attire into the ingesting location from bouquets to the items baskets Now we have to arrange all the things for our family and friends. Posted June 11 2009 edited with the encouragement of Dave Stephens i have started building several roller mills based on Hugh McDonalds design.

The housing less stands are normally arranged in horizontal-vertical no twist arrangement which allows no twist rolling which permits larger reduction and smoother rolling as it eliminates twisting oval into round passes as in the conventional oval to round sequence which results in less guide wear and simpler guide design. Wire rollers are used for rolling and reducing the diameter of a wire. In the process of rolling the roll contacts with the workpiece directly forcing the plastic change of the workpiece.

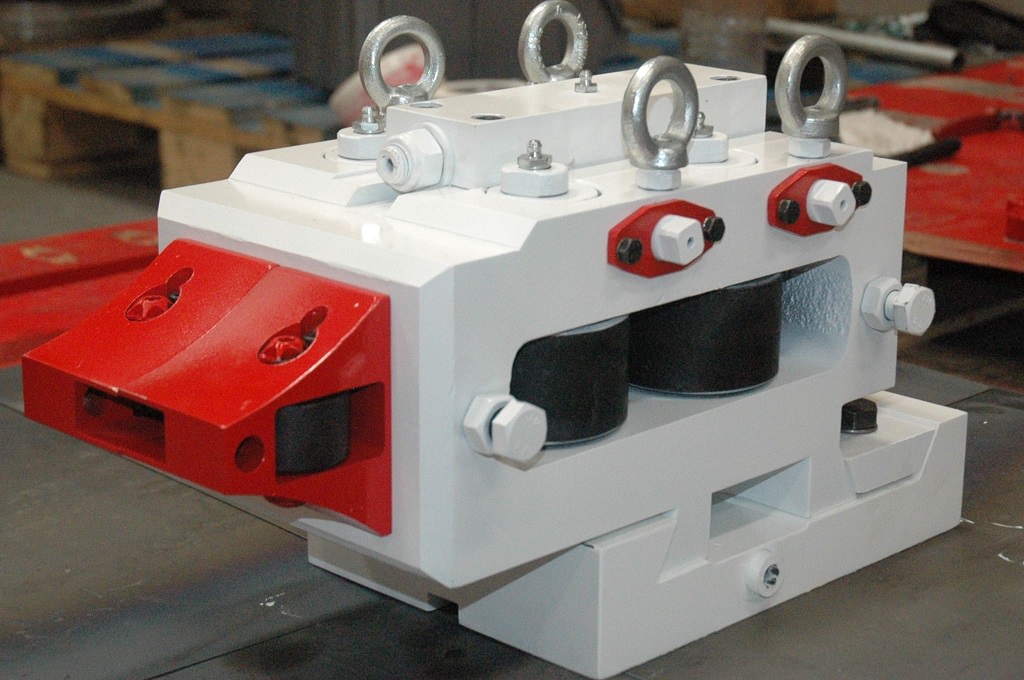

Combination rolling mills come with a roller that has a flat and groovy surface. Provide rolling mill solutions including rolling passes design production line setup and workshop layout according to your requirements. Roller Guide for rolling mill are a series of rollers that determine the angle and direction of the steel as it is guided through the rolling mill to the mill roll.

We provide the best quality of mill guides at a lower price. Most jewelers prefer a combination rolling mill because they work with different materials Flat rollers are used for reducing the thickness of sheet metal and imprinting patterns into the metal. Produce a Bend Progression or Flower Layout and design the Roll Forming Tooling around the flower.

Our roller entry guide is made in sliding type plus rolling type. Our rolling mill guides box is offered with the. Hot rolling mills are used for mass thickness reduction at high temperatures whereas the cold rolling mills are used as secondary rolling operations to attain more precise dimensional and mechanical properties.

These original concepts have been continuously developing to meet the market. The mill design innovation focuses on performance improvement of mechanical electrical hydraulic electronic control a nd programming components. Calculate the Estimated Strip Width.

For each new tooling requirement the designer should use the following steps.

Rolling Mill Guides Morgardshammar

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

Rolling Mill Guide Equipments Ispatguru

China Roller Guide Mill Guide Rolling Guide Guide Assembling China Guide Roller Guide

Rolling Mill Guides Roller Spares Equipment And Guide Hotiongroup

Mill Guides Guides Rollers Metallurgical Solutions Provider

What Are Roller Guide For Rolling Mill Kotobuki Sangyo Co Ltd

0 comments

Post a Comment